It’s great to be back in Banff!

The progress from other trades has been awesome! I’ve come back to see the millwork going up on our lime plaster ceilings in the dining room, and the drywall’s being installed throughout the home.

With such a positive start for the new year, we’ll have a super-productive month.

Having lost some time to travel early this week, we’ll be working straight through the weekend. We’ll be focusing on the kitchen, which means Venetian plastering the ceilings so we can finally take on the walls.

After arriving in town, we spent the week preparing all these areas for the next seven days of work. That meant we had to prime all the walls and ceilings, and float some walls to get them perfect and level so they’ll the right canvas for our work.

Old-school methods like floating walls don’t get a lot of talk on the home reno shows on TV, but they can really make the difference in the level of craftsmanship seen in work like ours.

Remember, we’re working with natural products like wood, and one warped 2×4 can mean a world of trouble for more than one trade on a job like this. Using today’s tools and yesterday’s know-how, our finishing techniques transform trouble spots that could make an elaborate plastering job like this seem less than perfect.

Sometimes, it’s what you don’t see at the end of the job that makes the difference between good work and great work.

Here’s the dining room. I can’t wait to see this room get further along!

The design is just amazing, and look at all the windows. I’m in love with the look of this space and keep trying to imagine the final result. With all the lines, the angles, the textures, the light, I know it will be stunning.

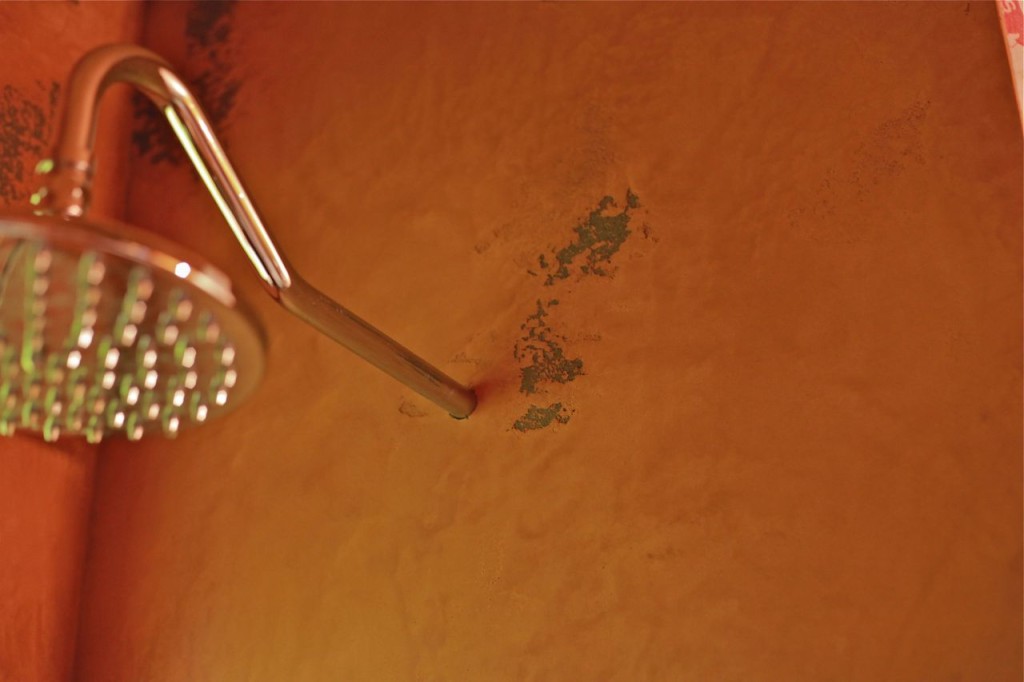

Below is a detailed shot of the first floor’s drop ceiling.

The architecture here blows me away, I can’t get enough of it! It demands that we spend way more time on the finishing work, sure, and our necks and shoulders are cramping up with the strain and effort it takes, but that’s the way it goes.

It’s honestly a privilege to work on such a high level of craftsmanship, in such an amazing natural setting, and if it takes an ice bag or two, that’s okay.

These ceilings are something else, aren’t they?

I think the slight sheen and subtle rustic texture bounce the light nicely while adding lots of character. What about you? Can you see this in a space for your project?

Can you imagine enjoying an Irish coffee, reading a mystery book, and the glow of a roaring fire casting shadows on this pitted ceiling? If you’re a designer, would your clients enjoy this?

Here’s a ceiling shot taken before the drywall was installed. You can really see the jagged edges and the revealed planks underneath.

Our work is literally cut out for us!

This is the biggest wall in the house, area-wise — and the tallest. We have an amazing design happening for this, which is carved in, with half-inch reveals. You don’t get to see how cool it looks until next week’s blog posting, though.

If you’re enjoying Week One of the exciting second phase of this big project in Banff, Alberta, then stick around for more excitement — now that almost all the prepping is done, you can expect to see change happening quickly and dramatically.

Stay tuned!

Wishing you a happy and healthy 2011,

Darrell Morrison