Well, we’re already three weeks into our massive Italian lime plaster commercial project in South Surrey, BC.

As you can imagine, a lot of work is going on around us on the project every day, so while we’re trying to keep productivity at a maximum, we also have to keep trade damage to our work at a minimum.

This week, focus has been on the main floor’s lobby, the corridors, ceilings, and that awesome barrel ceiling covered in Venetian plaster.

It’s a big challenge, a ceiling like that, but to know me is to know I love my job.

Everyone around me knows how much I dig the challenges and the change that come from project to project. My passion for what I do and for getting my clients what they want is what makes my work so successful.

This one’s got even more challenges, and people to satisfy, than anything I’ve done because it’s the largest project I’ve ever worked on, and I hope it proves I belong on both the artisan and big commercial side of plastering.

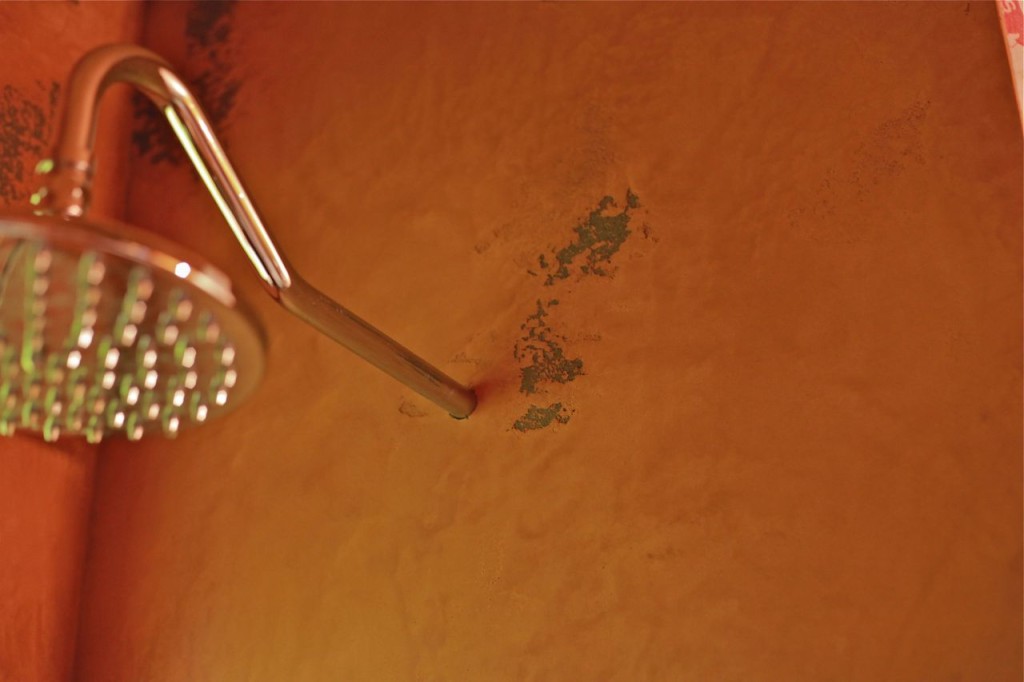

This barrel ceiling’s a huge focal point, so I took extra care and due diligence, as it’s a heavy use area and we want it looking as fantastic years from now as it does opening day.

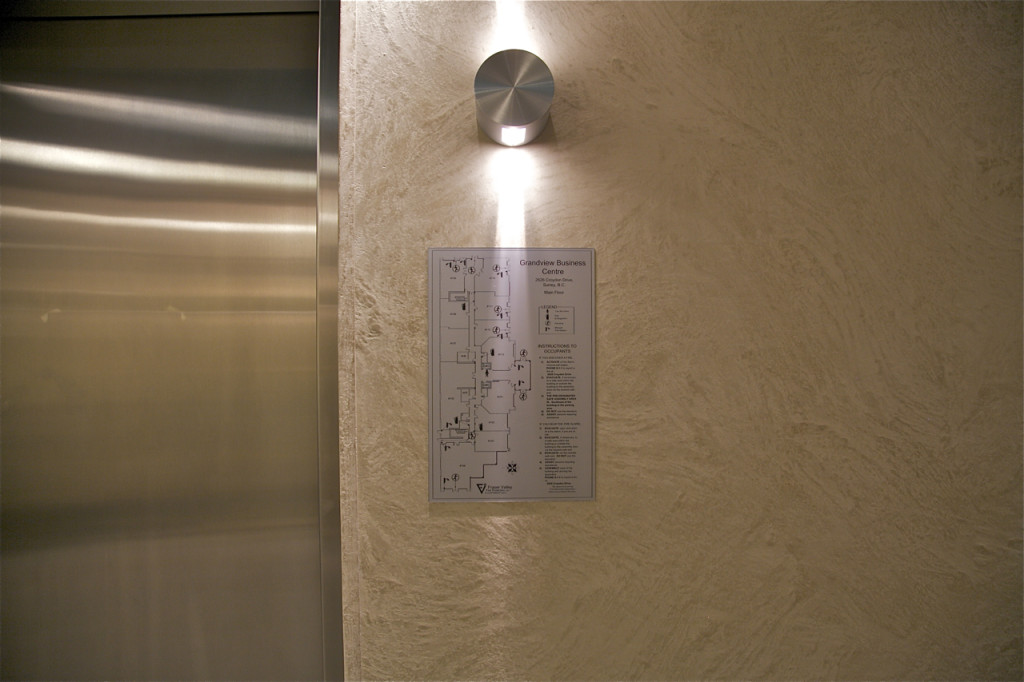

To get there, I started off by applying a two-coat Intonachino Lime plaster finish, and closed it up with a buffed super-smooth finish.

When you’re talking a “true” Venetian plaster, it’s actually a very thin finish. It can be somewhat delicate, and that’s something to consider on a project like this versus, say, a large home for a family of four. Given the massive building size, and the likelihood of foundation settling over coming months or years, I wanted a thicker plaster, just in case the building shifts any or nails decide to move any, and that extra coverage (and more work) should ensure longevity.

Craziness, I know, but it’s better safe than sorry, and it’s easier to do the job thoroughly the first time than to fix any problems a year or five years down the line.

Make sure your craftsmen don’t just think about how your job looks the day you have to sign the last check. You want them thinking about how that space will work for you over the coming years. Have that conversation with them, if you’re not sure they’re thinking in those terms — because they should be.

Look at this colour depth! This is what happens when I really push the envelope on the “maximum tint allowance” per bucket. Pay-off!

“Wax-on, wax-off.” Laying down the layers, pic by pic:

The end result? A stunning shiny show-stopper.

In this instance, it’s really a labour of love. It’s nine steps from start to finish — a lot of prepping, buffing, and grunt-work. There’s no easy way out on this one, it’s all about pushing through the burn thats the true nature of real venetian plaster.

At the end, all you see is how great it looks, and that’s okay with me.

Cheers,

Darrell Morrison.